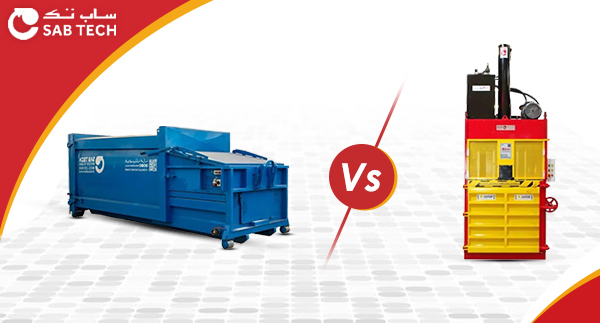

Balers and Compactors: The Key Differences

Properly managing waste is nowadays a critical activity for businesses.

Regardless of the size, businesses need to have a proper mechanism to dispose of their wastes and recycle them, if necessary.

You can have the proper waste management system only when you use a suitable machine for specific waste management purposes.

Despite waste management becoming increasingly popular among the business circuit, many business owners have yet to know the various aspects of waste management technology.

One of the common of such knowledge deficiencies is the difference between balers and compactors.

You should be able to distinguish them correctly, spotting their intrinsic differences.

If you are not aware of the differences between the two waste handling machines, you need to make some effort to understand them.

Fortunately, you have landed on the right article as it discusses the key differences between a baler and waste compactor in depth.

Balers and Compactors: the Purpose they Serve

From a superficial perspective, you can see an almost similar function of both the machines–they reduce the volume of waste materials placed in the machine.

Usually, both the machines have one or more hydraulic cylinders which force a platen, also called a ram, against the waste material to compress it. As a result, the size of the waste material becomes reduced, freeing up space.

As such, balers and compactors play one common role—compress waste to reduce its size. And that can help you eliminate the risk of fire incidents and reduce the time and expense of employees handling the waste materials.

Before exploring the key differences between the machines, let us walk through them, as that will create a mental foundation to understand the key differences.

Baler

For bulk pickup, you can regard balers as waste recycling machines used for baling recyclable materials, such as cardboard, paper, plastic, metal, etc.

Balers compress the recyclable wastes into compact bales, easing stacking and transportation for recycling.

There are different balers, such as horizontal balers, recycling balers, vertical balers, semi-auto horizontal balers, and stockroom balers.

The main benefits of using a baler are:

- Reduction in the time for managing waste materials

- Lessens space for recycling bins

- Renders a cleaner work environment

- Lowers waste disposal costs

- Eases handling of baled materials

Compactors

Another crucial waste handling machine is the industrial waste compactor, which is a perfect fit for businesses that generate and handle significant amounts of waste.

The working mechanism of a compactor involves compacting waste materials into a container. And it swaps out the waste for a new one when the container becomes full. So, the filled container can be transported to a landfill site or processing facility.

Compactors bear the flexibility of customizing to different needs. Besides, compactors come in a variety of sizes.

A typical compactor entails the following benefits:

- Reduction in the size of bulky wastes

- Eases transportation of waste materials

- Reduces waste management costs

The Difference Between Compactors and Balers

After learning what the machines are about, the underlying differences seem to have come to the fore. However, there is another critical difference between the two waste-handling machines you need to know before you decide to purchase one.

The main difference between the two machines lies in the materials they handle.

Balers are used to handle recyclable commodities that are on the way for storage and shipping.

On the other hand, compactors are used to reduce the size of the trash. As such, the machines provide the convenience of throwing away more waste material at a time.

Compactors provide the following benefits:

- Lesser space for landfills

- Reduction in carbon usage by hauling trucks

- Fewer truck trips

- Lesser waste handling costs

Which Equipment to Choose for Your Business?

It is time to address the critical question–of whether you should choose a baler or compactor for your business.

You should actuate a thoughtful approach rather than a straightforward one in deciding the right equipment for your business.

The most critical considerations are the type of waste materials your business generates and your sustainability goals.

So, two situations arise:

One, if your business generates a high volume of recyclable wastes and your goal is to improve recycling rates, investing in a baler is the right option.

Two, if your business produces significant volumes of waste and your goal is to reduce them, you need a compactor to manage the waste materials.

Therefore, you should analyze your requirement before investing in a piece of equipment as that will dictate the one to buy.

Choosing the Right Supplier

You should not undermine the need to choose a competent supplier as the quality of the equipment depends on the type of supplier.

Ensure you choose a trusted, reputed and experienced supplier. In addition to their market reputation, check their timeline in business.

Remember, a supplier that has been in the business for a long time knows the nitty-gritty aspects of the equipment and fulfilling customer needs.

Suppose you run your business in Saudi Arabia. In that case, you can choose the best-in-class waste compactors and balers from SABTECH, the best supplier of waste balers & compactors in Saudi Arabia. In addition, the company has also carved out a niche as a trusted supplier of waste recycling machines in Saudi Arabia.

Many potential customers regard SABTECH as one of the world-class baler manufacturers, known for supplying the best horizontal Automatic Baler in Saudi Arabia, among other excellent waste handling products.

Therefore, you can examine your needs to determine whether you need a waste compactor or baler. Afterwards, you can invest in a waste handling machine from a trustworthy supplier, like SABTECH.

The Final Say

You should refrain from investing in a waste handling machine straightaway as that can lead to purchasing the wrong equipment. As such, you should examine your waste handling needs to determine whether investing in a baler or compactor can be the right option. In addition, you need to choose a trustworthy supplier. If you fail to do so, you might end up investing in poor quality waste handling equipment, entailing money wastage.