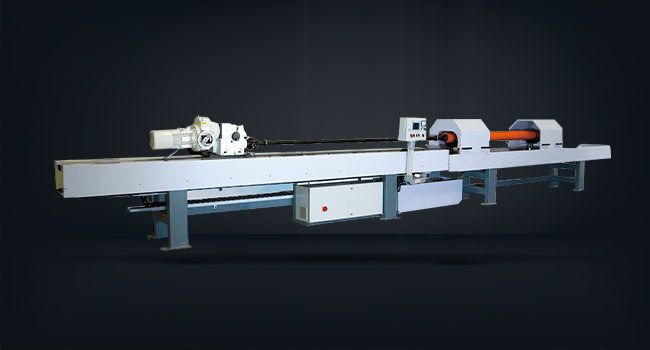

Expanding Services with Horizontal Honing Machine at Dammam

Expanding our servicing capacity at our Dammam facility, we like to welcome our Horizontal Honing Machine to our equipment’s family. Providing an even faster turnaround time and precision to our esteemed business partners, to continue growing our quality and speed of service.

We are proud to announce that we can now service tubes on the spot with the following ranges of diameter (I.D.): up to 450 mm and maximum stroke lengths up to 10000 mm.

So, what is a honing process?

A honing process creates the desired finish pattern inside of the cylinder tube bores with the final desired size.

Therefore, stones are rotated and reciprocated in the part with hone abrasive under controlled pressure, to produce a cross-hatch pattern in the surface of the honing part.

A clean finish is accomplished by expanding abrasive stones of suitable grit grade against the working surface through rotation and reciprocation.

Who can benefit from this service?

Businesses (such as factories, heavy equipment rental companies, mining companies, oil rigs, etc.) seeking to maintain and restore hydraulic powered equipment in a cost effective and timely manner.