All About Hydraulic Pumps & How to Repair Them: A Troubleshooting Guide

Regardless of whether you noticed or not, hydraulic pumps are in every production system. With the modern world depending so much on the pumps, it is essential to keep the systems working smoothly with proper inspection and maintenance.

Hydraulic pumps mostly work for years if properly maintained, but the pressure inside the pumps often leads to failures that need to be addressed to bring the pumps back to action.

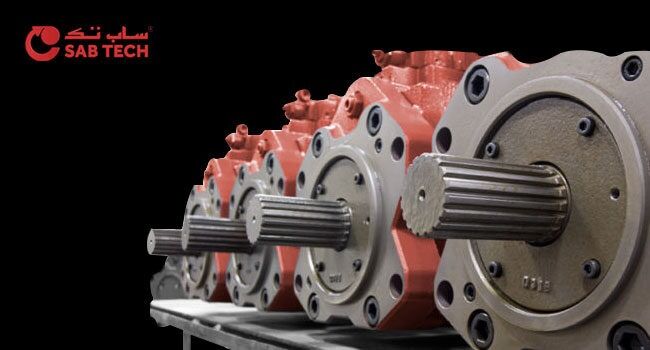

Hydraulic Pump Types

Before knowing about maintaining the devices, it is worthwhile to understand what different types of hydraulic pumps exist. There are mainly three types of hydraulic pumps—gear, piston, and vane.

Parallel to knowing the types, it also makes sense to understand how a hydraulic pump works.

Gear Pumps

Gear pumps are the most basic hydraulic pump. These pumps’ working involves fitting together the teeth of two gears, generating fluid chamber variations to push fluid flow. When fluid enters the intake chamber, the gear teeth create a large opening to allow plenty of liquid to get in. Subsequently, the gears turn, shrinking space, displacing the fluid, resulting in fluid flow.

Piston Pumps

Piston pumps are the most commonly used as they can perform complex applications. You will get to see such pumps mostly in manufacturing operations in high-pressure applications. Understanding the pump’s working will help if you regard the pump as a positive displacement pump. While working, a high-pressure seal in these pumps works reciprocally with a piston to move fluid. The mechanism empowers the pumps to operate under high pressure without affecting the fluid flow rate.

Vane Pumps

Vane pumps are straight-forward pumps that are ideal for lower-pressure applications with high flow rates. As these pumps are based on the positive displacement technique, they can work with several different vanes—flexible, swinging, rolling, external, and sliding. When the motor rotates, the vanes push fluid to the opposite side of the cavity inside the engine and squeeze it through discharge outlets.

Signs Indicating Necessity of Repair or Replacement of Your Pump

You should not miss out on monitoring your hydraulic pump as if you disregard the signs of any issues; it might lead to equipment failure, costly repairs, or even total replacement. So, how to know if the hydraulic pump is bad? The answer is the following signs:

Loud Noises

If you hear loud noise emanating from your hydraulic pump, consider it a warning signal that something is off. The hydraulic pump noise problem indicates that some parts have become faulty, needing repair or replacement. It can happen due to the wear and tear during operations. If your hydraulic pump is making a whining noise, then call a professional to inspect the issue and fix it.

Inside Leaks

If you see fluids anywhere inside the pump, be sure that something is wrong with it. The issue can be as simple as a seal or valve getting loose to complications, like a break in the line. With fluid inside the pump, there can be a pressure drop that will malfunction the pump.

Outside Leaks

If you see fluid on the pump’s exterior, then regard it as a serious issue, as the pump is on the verge of collapsing. It will help if you get an expert to assess whether the pump requires repair or replacement. When fluid leaks, the pressure reduces, increasing the temperature of the system. It negatively impacts the viscosity of the oil that further reduces the pressure in the pump.

High Working Temperatures

As dictated by the manufacturer, a specific level of viscosity is necessary for the hydraulic pump to function correctly. The fluid viscosity depends on the temperature and pressure, so they have to be maintained within limits specified by the manufacturer. If either of them is off, the pump can fail due to excessive strain. Look out for any hydraulic oil overheating symptoms, and ensure a free flow of the air around the reservoir.

Common Issues

The symptoms indicate that your pump is having a problem. The issues can also be the reason(s) behind hydraulic pump failure causes.

Fluid Leaks

Leaks are the most common issues. You can quickly identify leaks.

Air in Hydraulics

Air can enter into the hydraulics of the pump, resulting in weakening or slowing down the pump.

Cavitation

Hydraulic pump cavitation sound is an indicator of the formation of small air bubbles in the hydraulic fluid. It is known as cavitation. The air bubbles collapse, due to fluid pressure, releasing tremendous energy that can damage internal components.

Wear

Hydraulic pump components are prone to wear, which lessens the effectiveness of the pump. As loose parts do not fit with the necessary tightness, they lower the pump efficiency.

High Pump Temperatures

Improper heat load can be one of the reasons for the abrupt rise in temperature of the pump. You can determine the heat load by calculating the lost input power due to inefficiency—the lost power results in heat energy.

Stuck Internal Components

Internal components can get stuck inside the pump, making it difficult for the parts to move. And the results are noise and inefficiency. Stuck pieces can also make a pump fail to operate.

How to Repair Hydraulic Pump Issues?

Troubleshooting or repairing a hydraulic pump can be challenging. It will help if you keep in mind that improper troubleshooting can even damage your pump.

You can deploy a maintenance member on your staff to check for preliminary problems. Here are some standard troubleshooting steps:

- Check out for any visible points of fluid leakage

- Determine if there is any variation from the regular pump sound.

- Find out if any screw is loose

- Check out for any sign of cavitation

Conclusion

By now, you have come to know why you should not leave your defective pump unattended. If you turn a blind eye, then the efficiency of your operations will degrade, taking a toll on your productivity.

So, if your hydraulic pump is showing any sign of malfunctioning, get in touch with Sabtech, a world-class company that provides reliable hydraulic pump repairing service.